Product Consultation

Your email address will not be published. Required fields are marked *

In today's market, angle grinders are essential tools for various industries, from construction to automotive repair. A well-established Angle Grinder Factory goes beyond simply manufacturing equipment; it emphasizes quality, innovation, and precise manufacturing processes to meet global standards. This article explores how a top-tier angle grinder factory achieves high-quality standards, detailing its production processes, quality control, and innovation efforts that keep it competitive in the industry.

Advantages of an Angle Grinder Factory in Producing High-Quality Equipment

An angle grinder factory specializes in producing durable, efficient grinders that cater to professional and DIY users. These factories typically employ advanced production techniques and prioritize quality at every manufacturing stage, from sourcing materials to final assembly.

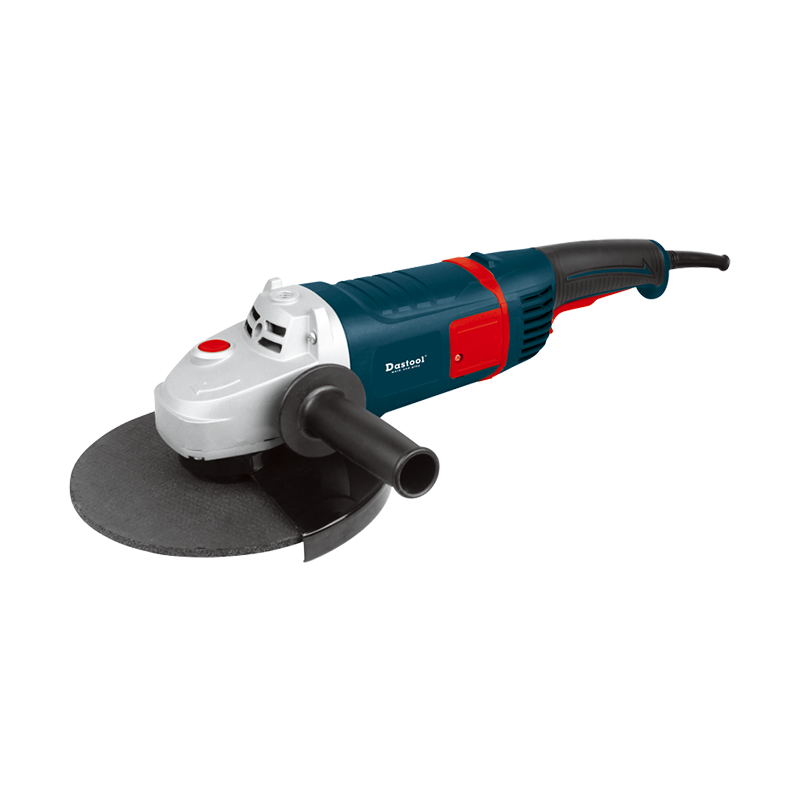

HJ2184-1700W Industry Level 125mm Short Handle Angle Grinde

The emphasis on quality control allows the factory to maintain strict standards, ensuring that each angle grinder performs optimally in various applications. Beyond producing just the grinders, the factory often manufactures a variety of angle grinder accessories, enhancing the versatility of its products and broadening its customer base. From cutting discs to polishing pads, these accessories are designed to complement the factory's angle grinders, providing users with a complete solution for their grinding needs.

Production Process: Ensuring Consistency and Quality

The production process in an angle grinder factory involves several key stages, each focusing on maintaining high quality and consistency. Here is a simplified breakdown of how these grinders are typically made:

Material Sourcing and Preparation

An angle grinder factory sources high-quality raw materials, such as hardened steel, to ensure the longevity of its products. These materials are carefully tested for strength and durability before entering the manufacturing line. This initial quality check is crucial as it sets the foundation for a reliable, long-lasting angle grinder.

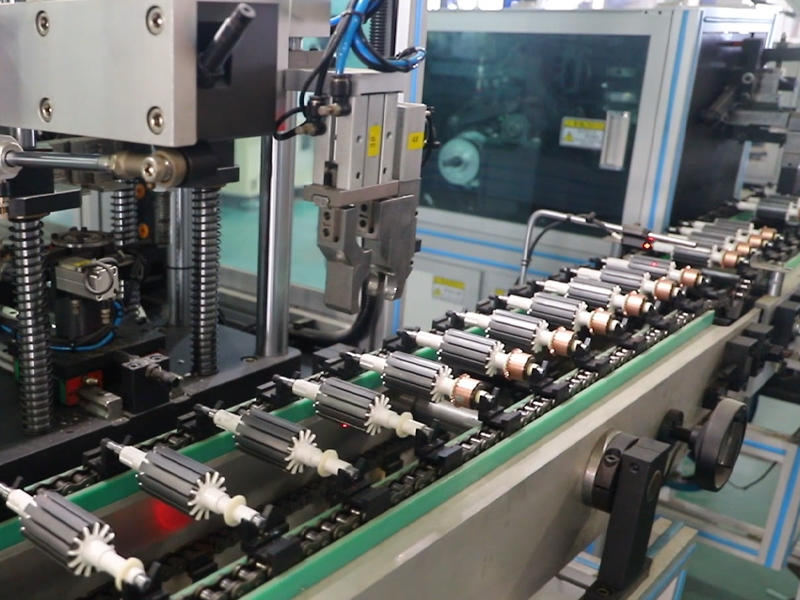

Component Manufacturing and Assembly

The manufacturing process begins with creating various components, including the motor, handle, and gear assembly. Each component is precision-engineered to ensure compatibility with other parts, enhancing the overall efficiency of the angle grinder. These factories often use automated machinery for parts assembly, allowing for high levels of precision and consistency across batches.

Quality Control and Testing

Quality control is an integral part of the production process. Every angle grinder goes through rigorous testing to ensure it meets specific standards for power output, durability, and safety. Some tests may involve simulating real-world conditions to ensure that the grinder performs effectively and remains safe to use in different environments.

Angle Grinder Accessories Production

Many factories also produce angle grinder accessories in-house, ensuring compatibility and quality across the product range. Accessories like cutting wheels, sanding discs, and polishing pads are crafted with the same high standards, providing users with reliable tools to handle various tasks. This in-house production approach guarantees that accessories work seamlessly with the factory's angle grinders, creating a complete toolkit for users.

Innovation and Technology Advancements in the Factory

Staying competitive in the angle grinder market requires a commitment to innovation. Leading angle grinder factories continually invest in new technologies to improve their products. Here are some key innovations often seen in advanced factories:

Enhanced Motor Efficiency

Many angle grinder factories focus on enhancing motor efficiency, resulting in grinders that offer more power without consuming excess energy. By integrating advanced motor technology, these factories produce grinders with improved torque, enabling them to handle tougher materials and provide longer operational life.

Improved Ergonomics

In response to user feedback, factories are now prioritizing ergonomics in design. Comfortable handles, vibration reduction features, and compact designs make grinders easier and safer to use over extended periods. Factories are also introducing lighter materials to reduce the overall weight, making their grinders more user-friendly.

Dust Protection and Cooling Mechanisms

Innovative angle grinder factories incorporate dust protection and cooling systems in their products to enhance durability. Dust protection prevents debris from entering the motor and affecting performance, while efficient cooling systems prevent overheating during prolonged use. These features extend the grinder's lifespan and ensure stable performance.

Digital Integration for Precision

Some factories are exploring digital integration, such as variable speed controls and digital displays, for greater control and precision. These advancements are particularly useful for professionals who require precise settings for different tasks. Digital integration reflects the factory's commitment to providing users with adaptable, high-tech tools.

The Importance of Angle Grinder Accessories for Versatility

Angle grinder accessories play a crucial role in expanding the functionality of grinders. Leading angle grinder factories understand this and prioritize creating compatible, high-quality accessories. Accessories like sanding discs, polishing pads, and cutting wheels allow users to take on diverse tasks without switching tools, making the grinder an all-in-one solution.

Producing accessories in-house also allows factories to maintain quality control and ensure each accessory is perfectly suited for their angle grinders. Users can confidently purchase these accessories, knowing they are engineered with the same standards as the grinder itself.

Choosing the Right Angle Grinder Factory: What to Look For

When selecting an angle grinder factory or supplier, consider the following factors:

*Quality Control: Look for factories with a solid reputation for rigorous quality control. Factories that implement comprehensive testing and quality assurance are more likely to deliver reliable, long-lasting products.

*Innovation: Leading factories often invest in research and development to improve their products. Choosing a factory that focuses on innovation means you'll benefit from the latest technology in angle grinders and accessories.

*Product Range: A versatile product range, including both grinders and accessories, indicates that the factory is committed to offering a complete solution for its customers. Factories with a broad range of angle grinder accessories provide added convenience for users looking to accomplish various tasks.

*Customer Support and Warranty: A reputable factory usually offers customer support and clear warranty policies. This is essential for users who require guidance on product usage or need assistance with maintenance.

.png?imageView2/2/format/jp2)

How Do You Choose the Right Screwdriver and Cordless Drill for DIY Projects?

Nov 01,2024

Key Features of China Angle Grinder Discs and Die Grinders Explained

Nov 15,2024Your email address will not be published. Required fields are marked *