Product Consultation

Your email address will not be published. Required fields are marked *

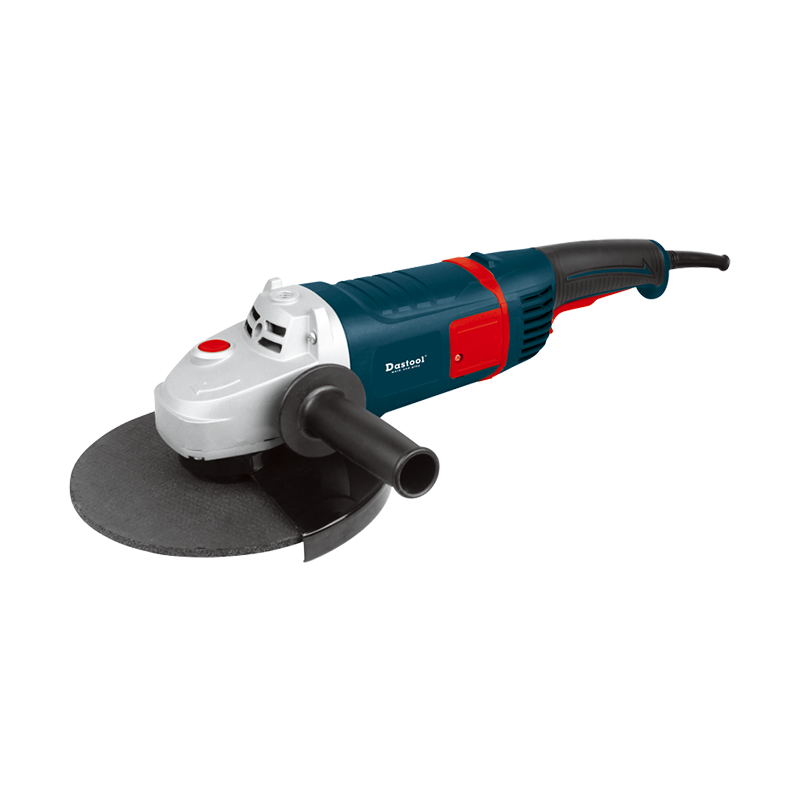

An angle grinder is one of the most versatile power tools that can handle a variety of tasks, from cutting and grinding to polishing and sanding. The key to unlocking its full potential lies in choosing the right angle grinder blades and angle grinder attachments for the job. This guide will introduce the most commonly used blades and attachments and explain their uses, helping you select the right tool for every task.

Angle grinder blades are specifically designed to cut or grind different materials. Choosing the right blade depends on the material you're working with and the job at hand. Here are some of the most common types of angle grinder blades:

1. Metal Cutting Blades

Metal cutting blades are ideal for cutting through various metals such as steel, aluminum, and copper. These blades are usually made from high-speed steel or abrasive materials designed to withstand the heat and friction generated during metal cutting. For tasks like cutting metal pipes, sheet metal, or removing bolts, metal cutting angle grinder blades are the better choice.

2. Diamond Blades

Diamond blades are widely used for cutting through tough materials such as stone, concrete, and tiles. They are embedded with small diamond particles that make them extremely hard and durable. Whether you're cutting paving slabs, concrete blocks, or ceramic tiles, diamond angle grinder blades are essential for getting a smooth, precise cut.

3. Wood Cutting Blades

While an angle grinder isn't typically associated with woodwork, there are angle grinder blades specifically designed for cutting and shaping wood. These blades feature fewer teeth than saw blades, which allows for quick material removal without the risk of the blade jamming. They are good for rough cutting, shaping, or carving wood.

4. Grinding Discs

Grinding discs are used for smoothing and shaping materials like metal or concrete. These angle grinder blades are essential for removing excess material or finishing surfaces after cutting. They are available in different grits, allowing for more aggressive grinding or fine finishing work.

Common Angle Grinder Attachments

In addition to blades, there are several angle grinder attachments that can expand the functionality of your tool. Whether you're polishing, sanding, or stripping materials, there's an attachment that can help. Here are some of the most useful angle grinder attachments:

1. Wire Brush Attachments

Wire brush attachments are ideal for removing rust, paint, or debris from surfaces. They are commonly used for metal surface preparation before painting or welding. These angle grinder attachments come in different forms, such as cup brushes and wire wheels, and they work efficiently for cleaning large surfaces or detailed areas.

2. Sanding Discs

Sanding discs are good for smoothing surfaces or removing excess material from wood, metal, or plastic. These angle grinder attachments are available in a variety of grits, making them versatile for heavy material removal or fine sanding jobs. For woodworkers or those looking to polish surfaces, sanding discs are a must-have attachment.

3. Polishing Pads

Polishing pads are used to give metal, stone, or plastic surfaces a shiny, smooth finish. These angle grinder attachments are often used in conjunction with polishing compounds or waxes to restore the appearance of metal items, polish granite countertops, or buff plastic surfaces. They are good for finishing work and ensuring a professional look.

4. Cutting Attachments

In addition to standard cutting blades, there are specialized angle grinder attachments for cutting different materials. For example, thin cut-off discs are ideal for precise, clean cuts in metal or plastic. Using the correct cutting attachment for the material ensures a smoother and more efficient cutting process.

How to Choose the Right Blade or Attachment

Selecting the right angle grinder blades and angle grinder attachments can significantly impact the efficiency and safety of your project. Here are a few tips for choosing the right tool for the job:

Consider the Material: Always choose a blade or attachment designed for the material you're working with. For instance, a metal cutting blade is inappropriate for cutting wood, and using a wood blade on metal could damage the blade and the material.

Match the Speed Rating: Ensure the speed rating of the blade or attachment matches your angle grinder's RPM (revolutions per minute). Using a blade with a lower speed rating than your grinder could lead to overheating or breakage.

Blade Size: Check your angle grinder's specifications to ensure you are using the correct blade size. Using an incorrectly sized blade can cause issues with balance and lead to accidents.

Maintenance: After use, clean and store your angle grinder blades and angle grinder attachments properly to prolong their lifespan. Regularly check for wear and replace blades or attachments that are worn out to maintain good performance.

Whether you're cutting metal, grinding concrete, or polishing surfaces, selecting the right angle grinder blades and angle grinder attachments is essential to achieving the 被better results. With a wide range of blades and attachments available, you can customize your angle grinder for various tasks and materials. Remember to choose the appropriate blade or attachment for the job, maintain your tools, and follow safety precautions for smooth and efficient operation.

A Deep Dive into Woodworking, Metal Processing, and Automotive Repair Tools

Sep 27,2024

Everyday Uses of Impact Drills and Electric Drills: From DIY to Professional Applications

Oct 11,2024Your email address will not be published. Required fields are marked *