Product Consultation

Your email address will not be published. Required fields are marked *

In industrial settings such as construction, manufacturing, and metalworking, choosing the right tools is crucial for maintaining efficiency and productivity. One tool that has become increasingly popular in these industries is the variable speed angle grinder. Compared to standard grinders, a variable speed angle grinder offers greater flexibility, precision, and control, making it an ideal choice for businesses that require versatility and performance. In this article, we’ll explore how a variable speed angle grinder can significantly improve efficiency in various industrial applications.

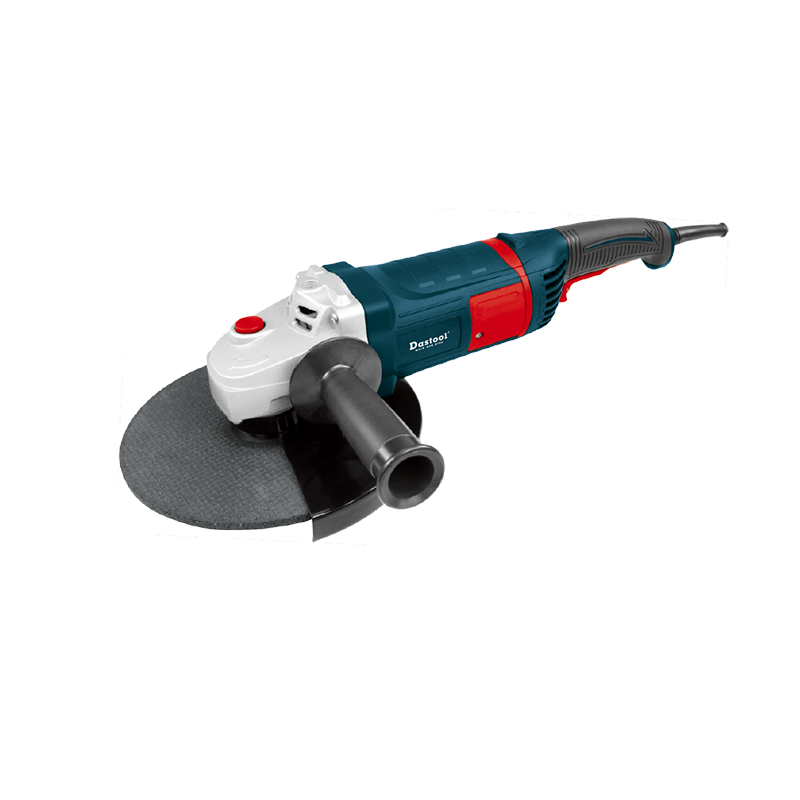

A variable speed angle grinder is a versatile power tool that can be used for grinding, cutting, polishing, and sanding. What sets it apart from a regular angle grinder is its adjustable speed settings, allowing users to control the tool’s RPM (revolutions per minute) depending on the material being worked on. This feature makes the variable speed angle grinder particularly useful for industrial applications that involve a variety of materials, such as metal, concrete, and stone.

Advantages of Using a Variable Speed Angle Grinder in Industrial Applications

1. Precision and Control

One of the biggest advantages of a variable speed angle grinder is the level of control it offers. When working on delicate materials or performing tasks that require high precision, such as finishing metal surfaces or cutting through sensitive materials, the adjustable speed allows operators to work at a pace that minimizes errors and material damage. This makes the tool especially useful for industries like metalworking and fabrication, where precision is critical.

For example, when polishing stainless steel or aluminum, running the grinder at a lower speed can prevent overheating and warping. In contrast, for cutting through tough materials like concrete or stone, a higher speed can be used to improve efficiency. The ability to switch speeds based on the task at hand gives workers more control and improves the overall quality of the job.

2. Versatility Across Different Materials

In industrial environments, workers often need to switch between different types of materials, such as metal, concrete, and stone. A variable speed angle grinder is designed to handle these varying materials with ease. Its adjustable speed settings allow users to optimize the tool’s performance for each material, resulting in cleaner cuts and smoother finishes.

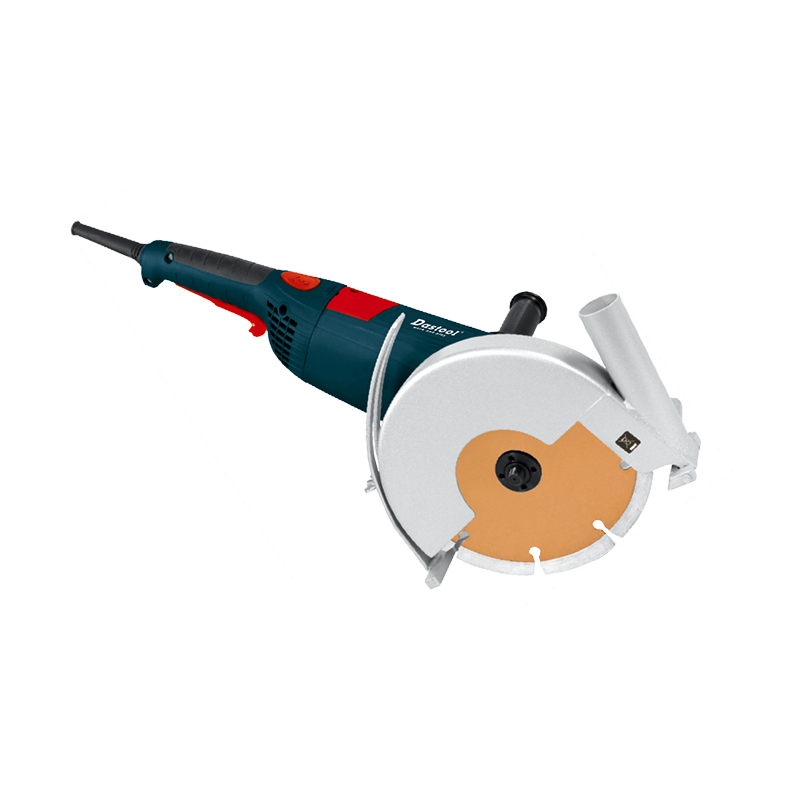

HJ2161-720W 125mm variable speed short handle Angle grinder

For instance, in construction, workers may need to cut through concrete one moment and then polish metal surfaces the next. A variable speed angle grinder can handle these transitions without the need for multiple tools, reducing downtime and boosting productivity. This versatility makes it a valuable asset for businesses in industries such as construction, manufacturing, and metalworking.

3. Improved Efficiency and Productivity

The ability to control the speed of an angle grinder means that workers can tailor their approach to specific tasks, resulting in faster completion times and fewer mistakes. In high-demand industrial environments, time is money, and any tool that can help workers perform their tasks more efficiently will ultimately contribute to cost savings.

For example, using a variable speed angle grinder for tasks such as surface grinding, cutting, or polishing allows workers to adjust the speed to effective setting for the material. This minimizes wear and tear on the tool, reduces the risk of damaging expensive materials, and ensures that the job is completed in a timely manner. As a result, businesses can take on more projects and meet deadlines more consistently.

4. Safety and Longevity

Working with an angle grinder at the wrong speed can increase the risk of accidents and injuries. For example, using a high-speed setting on a fragile material can cause the tool to slip, leading to accidents. With a variable speed angle grinder, workers can adjust the speed to match the material, reducing the risk of mishaps and ensuring a safer work environment.

Additionally, running the tool at the correct speed reduces the wear and tear on both the grinder and the materials, prolonging the life of the equipment. This not only reduces maintenance costs but also ensures that businesses can rely on their tools for longer periods without needing frequent replacements.

For industrial applications that demand versatility, precision, and efficiency, a variable speed angle grinder is an essential tool. Its ability to adapt to different materials and tasks makes it a valuable asset in industries such as construction, metalworking, and manufacturing. By investing in variable speed angle grinders, businesses can improve productivity, reduce material waste, and ensure a safer and more efficient working environment. Whether for grinding, cutting, or polishing, this tool offers a level of flexibility that standard grinders simply can’t match, making it a smart choice for any industrial operation.

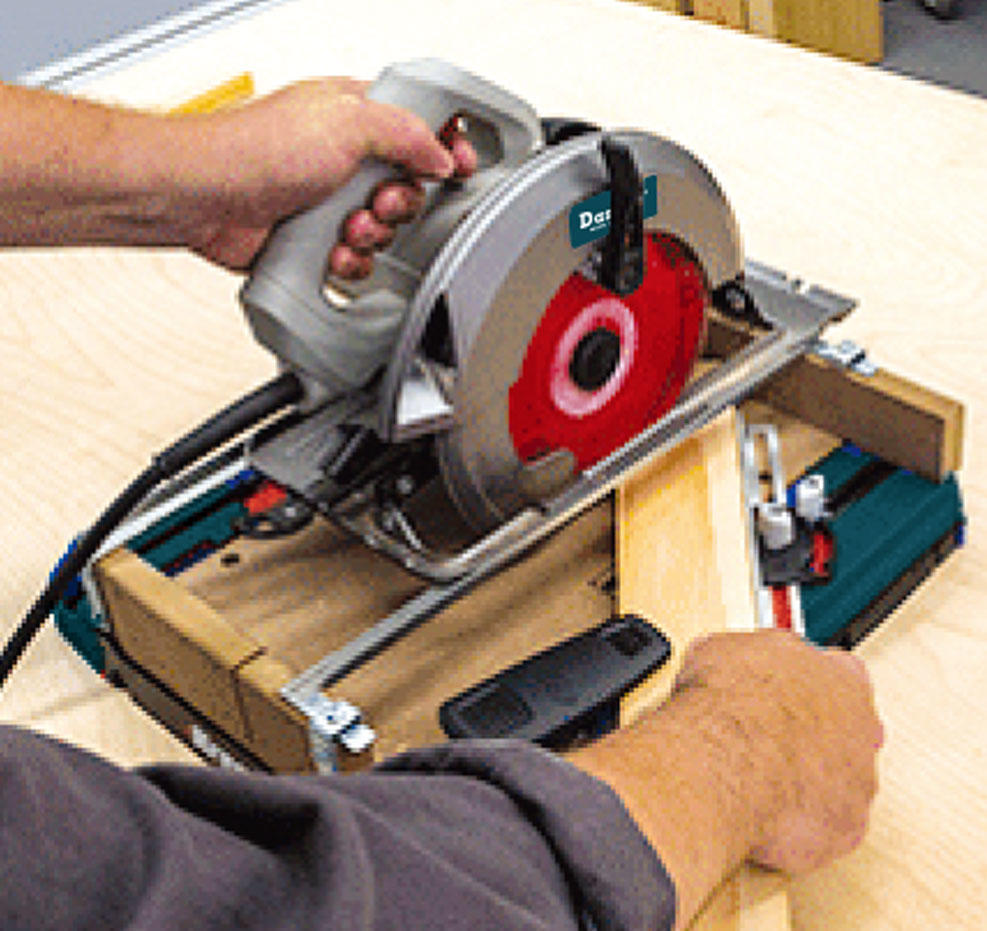

Maximizing Efficiency with a Concrete Grinder and Circular Saw for DIY Home Projects

Sep 13,2024

A Deep Dive into Woodworking, Metal Processing, and Automotive Repair Tools

Sep 27,2024Your email address will not be published. Required fields are marked *