Product Consultation

Your email address will not be published. Required fields are marked *

Selecting the right equipment is crucial for efficiency and precision. Two essential tools in this field are the concrete floor grinder and the wall cutter grinder. These machines play a vital role in surface preparation and wall cutting, making them indispensable for contractors and procurement professionals. Whether you are sourcing machinery for a large-scale project or looking to upgrade your existing equipment, understanding the features and capabilities of a concrete floor grinder and a wall cutter grinder will help you make an informed decision.

HJ2301-2200W 180mm concrete grinder

A concrete floor grinder is designed to smooth, polish, and prepare concrete surfaces by removing coatings, adhesives, and imperfections. It is commonly used in industrial warehouses, commercial spaces, and residential flooring projects. The efficiency of a concrete floor grinder depends on its power, grinding disc type, and operational speed. Some models come with dust collection systems to ensure a cleaner workspace, while others have adjustable settings to accommodate different flooring conditions. Procurement specialists should consider these factors when evaluating options, ensuring the machine meets project requirements while maintaining cost efficiency.

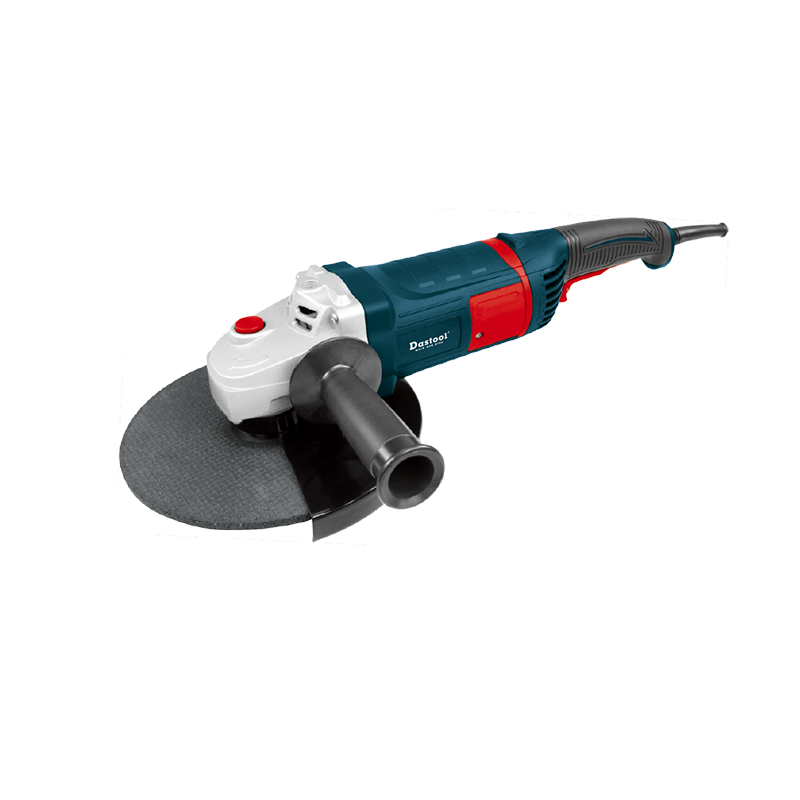

Similarly, a wall cutter grinder is essential for precise and efficient wall cutting in construction and remodeling projects. Whether cutting concrete, brick, or masonry, a wall cutter grinder allows contractors to create accurate channels for electrical wiring, plumbing installations, and expansion joints. The choice of blade type, cutting depth, and motor power significantly impacts performance. Many high-quality wall cutter grinders feature ergonomic designs and advanced safety mechanisms such as anti-kickback systems and dust extraction features to enhance usability and workplace safety.

Investing in a durable and high-performance concrete floor grinder and wall cutter grinder can improve project efficiency and reduce long-term maintenance costs. When purchasing these machines, procurement specialists should evaluate brand reputation, product durability, and warranty support. Comparing specifications across different manufacturers ensures that the selected concrete floor grinder or wall cutter grinder aligns with the specific needs of a project. Price is another factor, but balancing cost with quality is essential to avoid frequent repairs and replacements.

With the increasing demand for precision in construction work, manufacturers continue to innovate, producing more advanced concrete floor grinders and wall cutter grinders with enhanced features. Some models now come with intelligent controls, allowing operators to adjust settings for performance. Others incorporate noise and vibration reduction technologies, making them more comfortable to use over extended periods. As technology progresses, procurement professionals must stay updated on the latest advancements to make strategic purchasing decisions that improve operational efficiency.

Finding a reliable supplier for concrete floor grinders and wall cutter grinders is just as important as selecting the right model. Many professionals choose to buy directly from manufacturers, ensuring access to original parts and factory warranties. Others prefer to work with specialized construction equipment distributors who offer a range of brands and technical support. Online marketplaces also provide a convenient option, though buyers should carefully check product reviews and supplier credibility before making a purchase. Regardless of the purchasing channel, it is crucial to ensure that the concrete floor grinder and wall cutter grinder meet international safety and performance standards.

As construction projects continue to grow in scale and complexity, the need for high-quality equipment like concrete floor grinders and wall cutter grinders will only increase. Procurement professionals should focus on machines that provide efficiency, precision, and durability while also considering long-term operational costs. By carefully evaluating specifications, comparing suppliers, and keeping up with industry innovations, businesses can invest in the concrete floor grinder and wall cutter grinder to enhance productivity and achieve results in their projects.

Safety Precautions When Working with Belt and Polishing Sanders

Feb 07,2025

How to Improve Work Efficiency Using Angle Grinder Cutting Attachments

Feb 21,2025Your email address will not be published. Required fields are marked *