Product Consultation

Your email address will not be published. Required fields are marked *

In the field of precision processing in the manufacturing industry, Punching Nibble is an efficient and precise processing technology that plays a vital role in sheet metal processing. As a manufacturer, we know the importance of Punching Nibble, so we are committed to developing and improving this technology to meet the market demand for high-precision and high-efficiency processing.

Punching Nibble, as the name suggests, is a process that removes material through "biting". The core of this technology is the use of a set of precision-designed cutters that perform local and continuous bites on the metal sheet while rotating at high speed, thereby achieving precise material removal. This processing method can not only ensure the accuracy of processing, but also reduce the waste of materials to a certain extent and improve production efficiency.

Punching Nibble technology is widely used in our manufacturing process. It can be used to produce various complex metal parts, such as automobile parts, electronic equipment casings, mechanical structural parts, etc. These parts often require precise dimensions and fine surface treatments, and Punching Nibble technology meets these requirements.

Our Punching Nibble equipment adopts an advanced CNC system, which allows the operator to easily input processing parameters and achieve automated control. This kind of automation not only improves production efficiency, but also reduces human operation errors and further improves processing accuracy. In addition, our equipment is equipped with high-precision servo motors and stable guide rail systems to ensure stability and reliability during processing.

In terms of material selection, Punching Nibble technology also shows extremely high adaptability. Whether it is stainless steel, aluminum alloy, copper alloy or other metal materials, our Punching Nibble equipment can handle it with ease. This wide range of material adaptability allows our customers to choose the most suitable material for processing according to their own needs.

In order to improve processing efficiency, our Punching Nibble equipment also adopts a multi-station design. This means that multiple processing tasks can be performed simultaneously on the same equipment, greatly shortening the production cycle. At the same time, we have also equipped the equipment with a quick mold change system, making switching between different products faster and easier.

No expense has been spared when it comes to safety with our Punching Nibble devices. The equipment adopts multiple safety protection measures, including emergency stop buttons, safety doors, etc., to ensure the safety of operators. In addition, the equipment's operating system also has a fault self-diagnosis function, which can detect and prompt potential faults in time to avoid production interruption.

Environmental protection is also an important factor we consider when designing Punching Nibble equipment. Our equipment produces low noise and vibration during processing, minimizing the impact on the environment. At the same time, the equipment's waste collection system can effectively collect waste generated during processing to facilitate subsequent recycling and processing.

In order to meet the needs of different customers, our Punching Nibble equipment provides a variety of configuration options. Customers can choose the most appropriate equipment configuration based on their production scale and processing requirements. At the same time, we also provide customized services and can design and manufacture special Punching Nibble equipment according to customers' specific needs.

In terms of after-sales service, we provide customers with comprehensive technical support and training services. Our technicians can provide customers with equipment operation training to help them quickly master the use of the equipment. At the same time, our service team can also provide regular equipment maintenance and inspection services to ensure long-term stable operation of the equipment.

In summary, Punching Nibble technology plays an integral role in our manufacturing industry. It has won the recognition and trust of customers with its high precision, high efficiency, high adaptability and environmental protection. As a manufacturer, we will continue to be committed to the research, development and innovation of Punching Nibble technology to provide customers with better products and services.

Efficient Cleaning with a Cordless Pressure Washer

May 24,2024

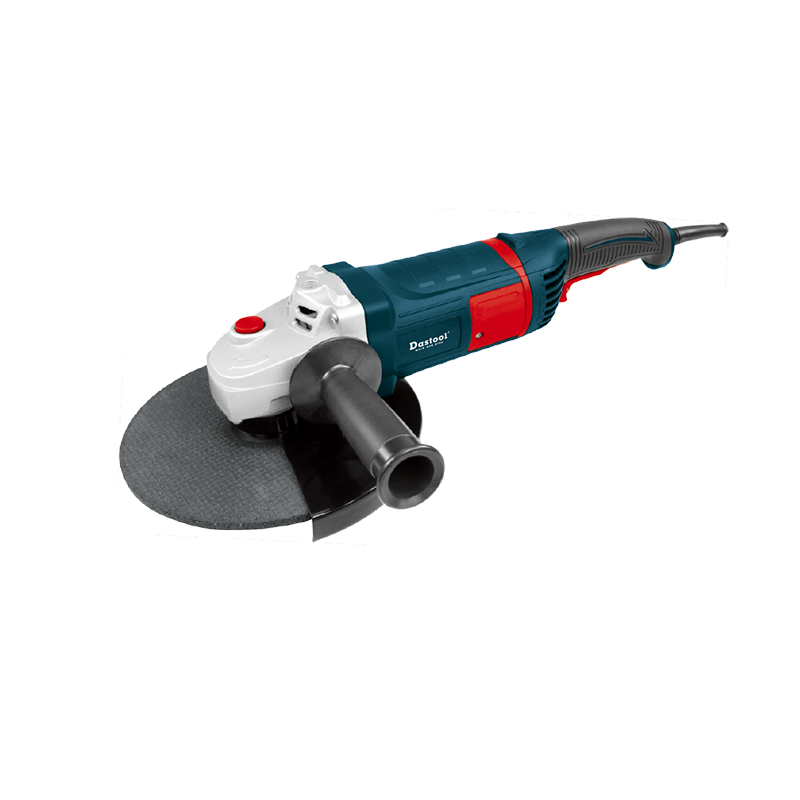

Full Analysis of Angle Grinder Accessories

Jun 07,2024Your email address will not be published. Required fields are marked *