Product Consultation

Your email address will not be published. Required fields are marked *

The Unsung Hero of Metalworking: How Die Grinders Tackle the Toughest Jobs with Ease

Jan 31,2025

Electric Drill vs. Manual Tools: Why You Need a Brick Drill Bit for Construction Jobs

Jan 24,2025

The Impact of Cordless Angle Grinders and Variable Speed Grinders on Efficiency in Construction

Jan 17,2025

As a professional power tool manufacturer, we are well aware of the importance of electric drills in modern manufacturing. In this article, I will detail the uses and features of electric drills and how we provide the correct solutions for our customers.

Let me introduce you to our electric drill products. Our power drills are powered by electricity and can be used in a wide range of manufacturing industries. We provide various types of electric drills, including DC electric drills, AC electric drills and brushless electric drills, to meet the needs of different scenarios. These electric drills have performance features such as high speed, high torque, and low noise, ensuring that users can complete tasks efficiently in various environments.

The main function of our electric drill is drilling holes and tightening screws. In the construction industry, engineers need to drill holes in hard materials such as concrete and brick walls to install pipes, wires and other equipment. Our power drills handle these challenges with ease thanks to their high RPM and high torque characteristics. In addition, in the furniture manufacturing industry, carpenters also need to use our electric drills to process wood and make exquisite furniture.

Our power drills are designed to be lightweight and easy to carry and move. This allows users to easily complete tasks in various environments without worrying about the weight and size of the tool. Our electric drill is easy to operate, and even first-time users can get started quickly. We provide detailed instruction manuals and online tutorials to help users better understand and use our products. We attach great importance to the safety of our users, so we fully consider safety factors during the design and production process. Our electric drills have safety features such as overheating protection and short-circuit protection to ensure users are protected from accidental injuries during use. Our electric drills use high-quality materials and strict production processes to ensure product durability and reliability. Under normal use, our electric drills can provide users with long service.

In addition, the quality of our impact drills is also very good. Let me introduce you to our impact drill products. An impact drill is a special type of electric drill that works by generating impact force while the drill bit rotates, thereby improving drilling efficiency. Our impact drills are widely used in construction, decoration, furniture manufacturing and other fields. Especially in scenarios where rapid drilling is required, our products show significant advantages.

Next, I will introduce the characteristics of our impact drill. Our impact drill generates impact force while rotating, making it easier for the drill bit to penetrate hard materials. This greatly increases the drilling speed and saves working time. Our impact drills can not only drill holes, but also tighten screws, remove parts, and more. This allows users to perform various tasks without changing tools, improving work efficiency.

Our impact drills are easy to operate, so even first-time users can get started quickly. We provide detailed instruction manuals and online tutorials to help users better understand and use our products. We attach great importance to the safety of our users, so we fully consider safety factors during the design and production process. Our impact drills have safety features such as overheating protection and short-circuit protection to ensure users are protected from accidental injuries during use.

All in all, our electric drills and impact drills have done a good job in quality control. I hope everyone can try and buy our products, which will give you a more efficient experience.

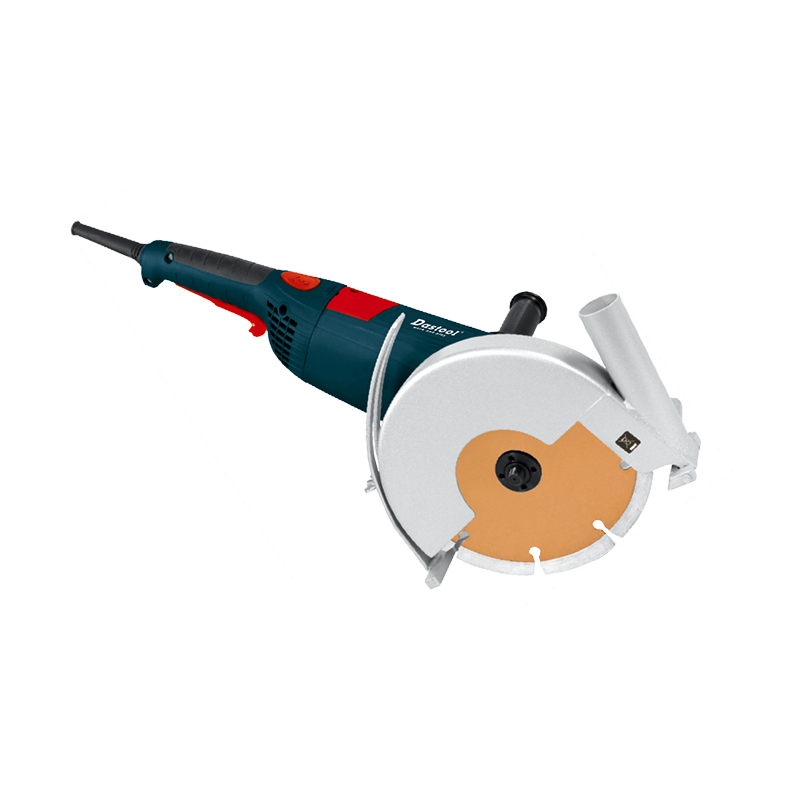

Exploring the Versatility of Wall Cutter Drill Machines for Construction and Renovation Projects

Mar 29,2024

We Focus on Efficiency and Durability

Apr 12,2024Your email address will not be published. Required fields are marked *