The Versatile Angle Grinder: A Powerful Tool for Cutting, Grinding, and Polishing

Introduction:

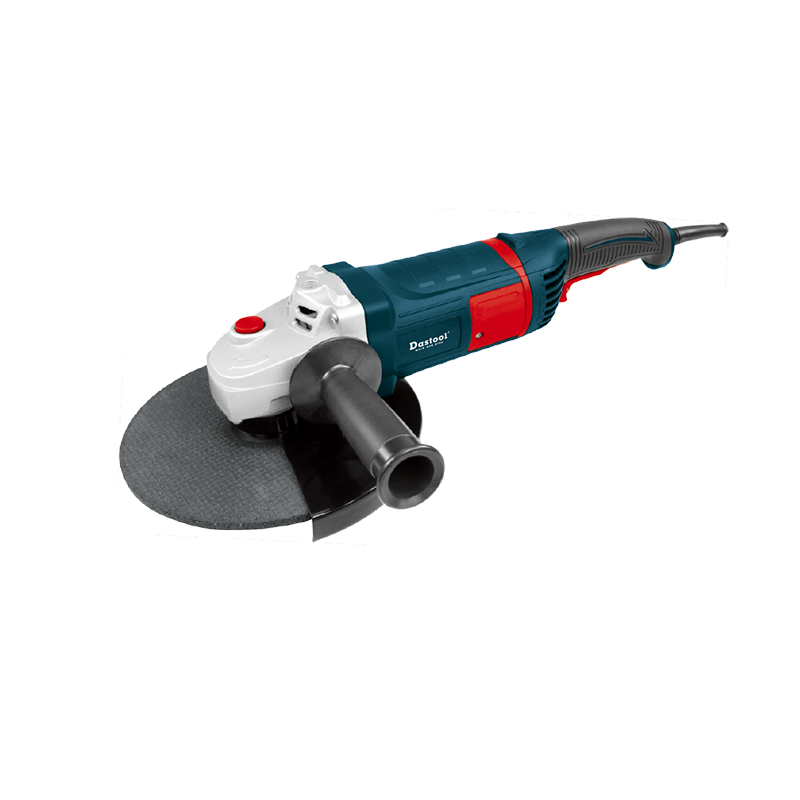

The angle grinder, a versatile and indispensable tool in various industries, has revolutionized the way professionals and DIY enthusiasts approach cutting, grinding, and polishing tasks. With its compact design, powerful motor, and interchangeable abrasive discs, the angle grinder has become a go-to tool for a wide range of applications. In this article, we will explore the key features, uses, and safety considerations of the angle grinder, shedding light on its importance in construction, metalworking, and fabrication projects.

I. Key Features:

The angle grinder's design comprises a small, handheld device with an electric motor that drives a geared head at a right angle to the motor shaft. This unique configuration allows for easy maneuverability and access to hard-to-reach areas. Angle grinders are available in various sizes and power ratings, catering to different application requirements.

One of the standout features of an angle grinder is its interchangeable abrasive discs. These discs come in a variety of types and sizes, including cutting discs, grinding wheels, flap discs, and sanding pads. Users can quickly swap discs based on the task at hand, making the angle grinder highly adaptable.

II. Versatile Applications:

Angle grinders find extensive use in multiple industries due to their versatility. In the construction industry, they are utilized for cutting through various materials like metal, concrete, tiles, and stone. Whether it's creating precise cuts for installation or removing excess material, the angle grinder proves indispensable.

Metalworking professionals often rely on angle grinders for shaping, deburring, and polishing metal surfaces. The cutting discs are adept at removing burrs, weld spatter, and sharp edges, while grinding wheels can smooth and prepare surfaces for welding or painting. Moreover, angle grinders equipped with wire brushes can effectively remove rust and corrosion from metal objects.

In fabrication shops, angle grinders are the tool of choice for cutting and shaping materials such as steel, aluminum, and fiberglass. With the appropriate cutting disc, intricate curves and angles can be achieved effortlessly, allowing for precise fabrication.

III. Safety Considerations:

While angle grinders are powerful and efficient tools, it is crucial to prioritize safety during their operation. Users must wear appropriate protective gear, including safety glasses or goggles, gloves, and hearing protection. It is also recommended to use a dust mask when working in dusty environments.

Proper handling and grip are essential to maintain control over the angle grinder. The tool should always be held with both hands, ensuring a firm grip to prevent accidental slips or loss of control.

Additionally, regular inspection and maintenance of the angle grinder are vital. Checking the integrity of the power cord, ensuring the disc is securely attached, and verifying that the guard is in place are important steps to prevent accidents.

Conclusion:

The angle grinder has become an indispensable tool, enabling professionals and hobbyists alike to accomplish a wide range of cutting, grinding, and polishing tasks with precision and efficiency. Its compact design, powerful motor, and interchangeable abrasive discs make it adaptable to various materials and applications. From construction to metalworking and fabrication, the angle grinder has transformed the way tasks are accomplished. By following proper safety precautions and using the tool responsibly, users can harness the full potential of this versatile powerhouse in their projects.

English

English Español

Español