Product Consultation

Your email address will not be published. Required fields are marked *

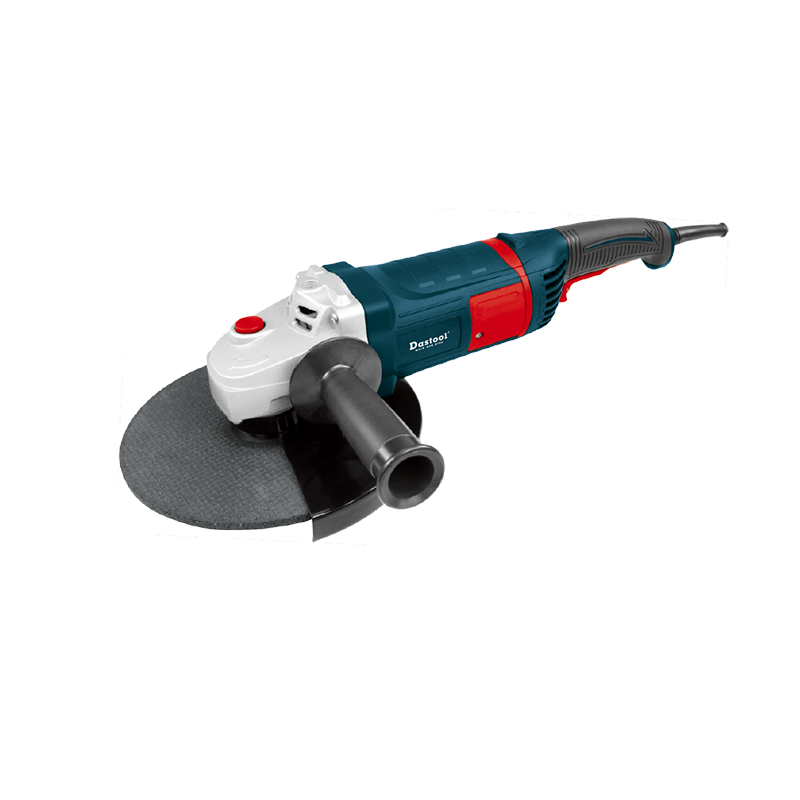

In today's industrial and construction fields, angle grinders have become one of the indispensable tools. As Angle Grinder Manufacturers, we understand the versatility of angle grinders and the importance of their accessories. The variety of angle grinder attachments allows this tool to adapt to a variety of different work environments and needs. This article will detail the types of angle grinder accessories and their applications.

Let’s start with the basic angle grinder accessory – the cutting blade. The cutting blade is one of the commonly used accessories for angle grinders and is used to cut a variety of hard materials such as metal, stone, and ceramics. Depending on the cutting material, the material and tooth shape of the cutting blade will also be different. For example, metal cutting discs are often made of diamond or silicon carbide to ensure cutting efficiency and durability.

Next are grinding discs, another common type found in angle grinder attachments. Grinding discs are mainly used for surface grinding and polishing of metal, wood and other materials. Unlike cutting discs, sanding discs usually have a smoother surface to allow for a finer finish. In addition, the grit size of the grinding discs is also available in a variety of options to meet the grinding needs of different roughnesses.

In addition to cutting and grinding, angle grinder attachments also include polishing discs. Polishing discs are mainly used for polishing metal surfaces. They can remove burrs and unevenness on the surface of the material to make the surface smoother. The material and particle size selection of polishing discs is similar to that of abrasive discs, but the abrasive particles of polishing discs are usually finer to achieve a higher surface finish.

As Angle Grinder Manufacturers, we understand the importance of diversity in accessories to meet the needs of different users. Therefore, we also offer a range of angle grinder accessories with special functions, such as grooving knives, drill bits, polishing brushes and more. Grooving knives are used to create grooves or cut straight lines in materials, while drill bits can be used for drilling operations. Polishing brushes are suitable for removing rust and dirt from the surface of materials to prepare for subsequent sanding or painting work.

When it comes to safety, the design of angle grinder attachments cannot be ignored either. To protect operator safety, many angle grinder attachments are equipped with safety locking mechanisms to prevent the attachment from accidentally falling off during operation. In addition, some accessories also adopt shock-absorbing designs to reduce vibration during operation and improve operating comfort and safety.

As technology develops, angle grinder accessories are constantly innovating. For example, some high-end angle grinder accessories use ceramic abrasives, which have higher hardness and wear resistance and can significantly improve cutting and grinding efficiency.

As an Angle Grinder Manufacturer, we not only focus on the quality and performance of our products, we are also committed to providing comprehensive after-sales service. We provide detailed usage instructions and maintenance guides for each angle grinder attachment to ensure users can use these attachments correctly and safely. In addition, we also provide regular training and technical support to help users solve problems encountered during use.

In summary, the diversity and functionality of angle grinder attachments are important reasons for their widespread use in industry and construction. As an Angle Grinder Manufacturer, we will continue to be committed to developing and producing high-quality angle grinder accessories to meet the needs of different users. We believe that through continuous innovation and improvement, our angle grinder accessories will be able to provide users with more efficient, safe and environmentally friendly solutions.

Advantages of Variable Speed Angle Grinders in the Construction Industry

Jul 12,2024

Steps to Ensure the Angle Grinder Disc Is Installed Correctly

Jul 26,2024Your email address will not be published. Required fields are marked *