Product Consultation

Your email address will not be published. Required fields are marked *

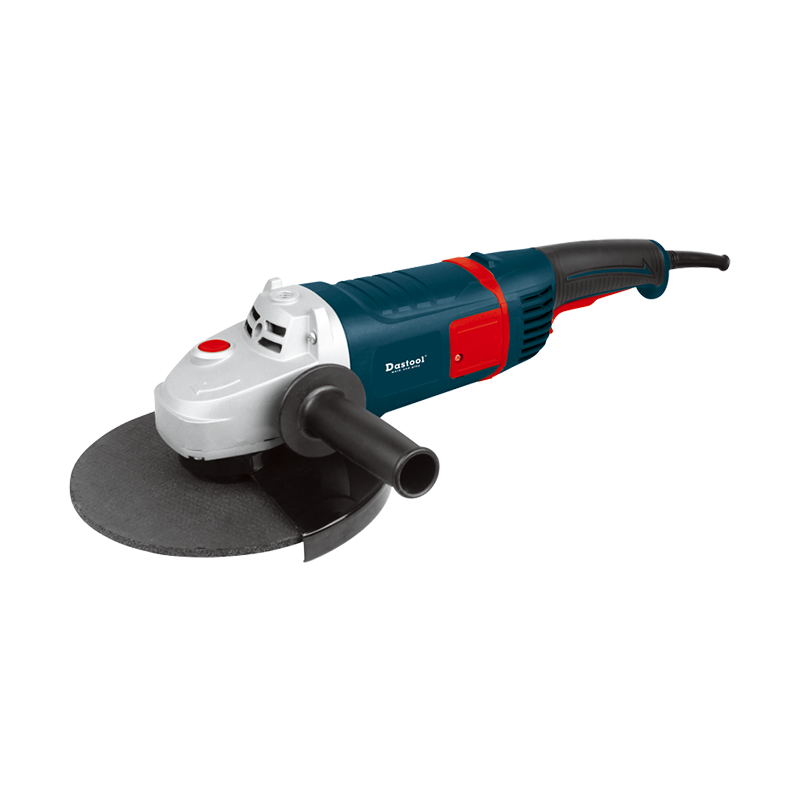

In the process of manufacturing and using angle grinders, safe and correct operation is crucial. As a professional angle grinder manufacturer, we know the importance of correctly installing angle grinder discs. This article will provide you with a detailed operating guide to ensure you can complete your job safely and efficiently when using an angle grinder.

Knowing the specifications of your angle grinder is the important step in installing the angle grinder disc. Different angle grinder manufacturers may produce equipment with different powers and sizes, so it is important to ensure that the grinding disc you choose is compatible with your equipment. Usually, the diameter and hole diameter of the grinding disc will be marked on the packaging of the grinding disc and in the manual of the angle grinder.

Before you begin installation, make sure you have on all necessary personal protective equipment, including safety glasses, dust mask, earplugs or earmuffs, and wear-resistant gloves. These gears protect you from flying debris and noise.

Next, disconnect the power source to the angle grinder. This is a basic principle of safe operation, and no matter what maintenance or replacement work you perform, you should ensure that the equipment is powered off.

Now you can start disassembling the angle grinder. Typically, this involves loosening the nuts or clamps that hold the grinding disc in place. Using an appropriate wrench or tool, carefully loosen these parts. During disassembly, be sure not to use excessive force to avoid damaging the angle grinder or disc.

Once the grinding disc is removed, you can inspect the inside of the angle grinder to make sure there are no remaining debris or dust. If necessary, use a soft brush or compressed air to clean the inside of the angle grinder.

Now you are ready to install your new angle grinder disc. Before installation, inspect the grinding plate for any cracks, chips, or other signs of damage. Damaged grinding discs may break during use, posing a serious safety risk.

Align the new angle grinder disc with the angle grinder shaft and carefully push it into place. Make sure the grinding disc is aligned with the shaft and not deflected. Once the grinding plate is in place, you can begin reinstalling the retaining nuts or clamps. Using a wrench or tool, tighten the nuts evenly until the disc is securely seated on the angle grinder.

After installation, check again whether the grinding disc is secure and make sure there are no loose parts. You can then reconnect the angle grinder to power and give it a test run. During the trial operation, observe whether the grinding plate rotates smoothly and whether there are any abnormal sounds or vibrations.

As an angle grinder manufacturer, we recommend that you inspect and replace your grinding discs regularly to ensure good performance and longevity of your equipment. The wear of grinding discs will increase with time, so regular inspection and replacement are key to maintaining safe operation of the equipment.

Finally, don’t forget to double-check the mounting of the grinding disc and the general condition of the equipment before each use of the angle grinder. Prevention is always better than cure, and by taking these precautions, you can minimize the risk of equipment failure and accidents.

In summary, proper installation of the angle grinder disc is a critical step in ensuring safe and efficient operation of the equipment. As an angle grinder manufacturer, we are committed to providing high-quality products and detailed operating instructions to help our customers achieve the better work results. By following the guidelines in this article, you can ensure that your angle grinder disc is installed properly so that it performs well in a variety of applications.

Multifunctional Angle Grinder Accessories

Jul 19,2024

Why workers choose our angle grinder?

Aug 02,2024Your email address will not be published. Required fields are marked *